Saddle Stitched Books FAQ

Saddle stitched books are commonly referred to as “booklets”, and are a great option in book binding when a page count is too low for perfect binding and books need to lay flat. In this section, we’ll explain the requirements, limitations and features of saddle stitched booklets.

Saddle Stitched Booklet Requirements

Page Count

Saddle stitched booklets work in page counts that are a multiple of 4, as they are printed in a 4 page signature layout.

The minimum number of pages for any saddle-stitched booklet is 8 pages.

The maximum number of pages for a saddle stitched booklet depends on the type of paper used and the size of the book. Usually, 40-56 pgs is the maximum number of pages we recommend for stitched booklets, but we can produce up to 100 pgs if they paper is very thin (such as 40 lb offset) and the finished size of the book is at least 5.5″ x 8.5″.

Finished Sizes

We can produce booklets as small as 3.5″ wide by 3.5″ high when trimmed to final size, but this does require additional processing in bindery to manually trim the books. Whenever manual processing is required, the cost will increase to account for the time and labour required.

The maximum size for a saddle stitched booklet is 9″ wide by 11″ high in portrait orientations, and 9″ wide by 11″ high in landscape orientations.

Flat Sizes

The flat size of a booklet refers to the dimensions of the pages when the booklet is open. For example, a booklet with a flat size of 17″ wide by 11″ high means that 17″ is the width of two pages side by side. To calculate the finished size, we divide the flat width by 2, which yields 8.5″ wide, which means the size of each finished page is 8.5″ wide by 11″ high.

Features of Booklets

Lay Flat

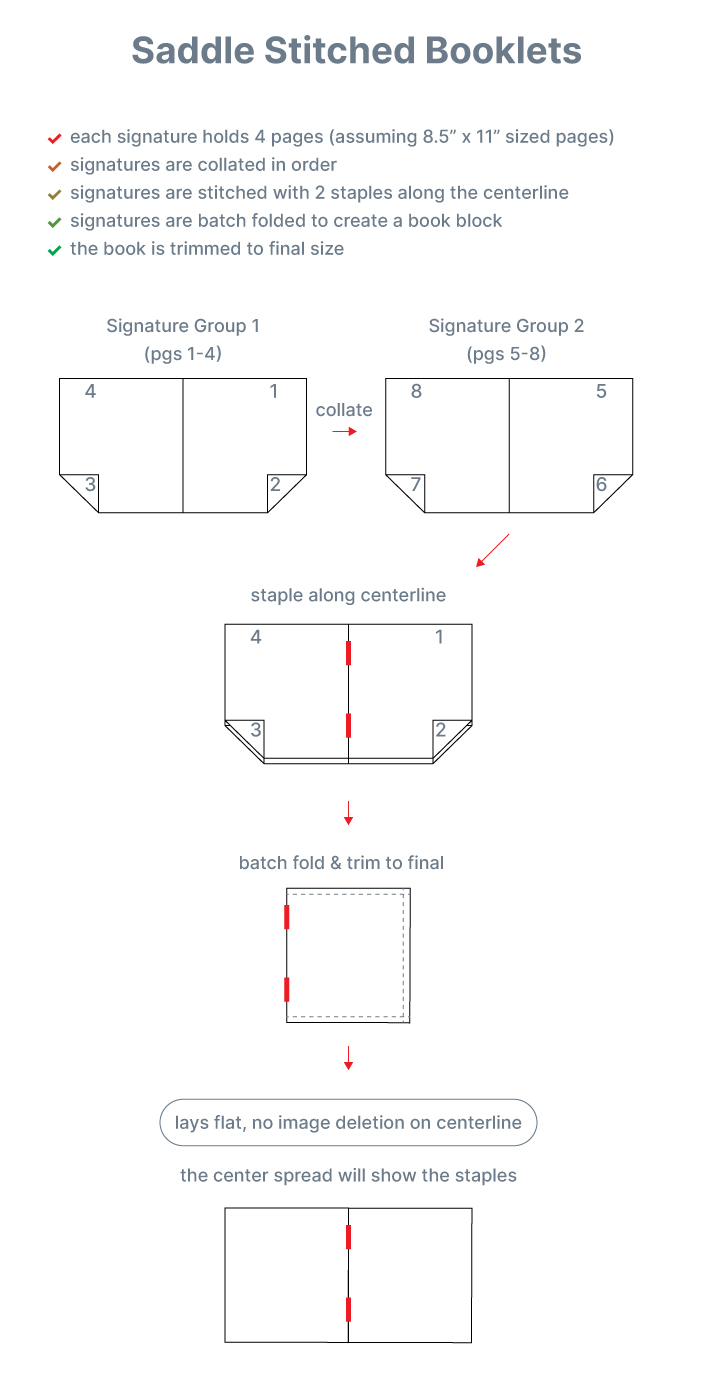

All saddle-stitched booklets will lay flat, as they are folded along the center of each signature to produce a seamless overlap on the centerline. So you can have cross-over spreads with no image loss along the centerline when folded and bound.

Self Cover & Different Cover

Each saddle-stitched booklet project will require a cover, which can either be printed on the same paper as the interior pages are, or a different paper than the interior.

When the cover and interior paper are the same, the booklet is referred to as a “self cover”. When the cover and interior paper are different (such as a thicker cover), then the booklet is referred to as a “different cover”.

Self-cover booklets are the most cost-effective option, as they provide minimal setups on bindery equipment and can be bound faster than a different cover booklet is. Different cover booklets may require the cover to be printed on a thicker paper, like cardstock, which will require scoring before it can be collated onto the interior pages before bindery. This extra step in scoring the covers and collating adds costs to the bindery process, making different cover booklets more expensive.

Artwork Setup

How To Supply Pages & Files

When you’re ready to send your PDF files to us for printing, please supply your files as follows:

- Single pages, assembled in order, with 1/8″ bleeds, and a page count that is a multiple of 4

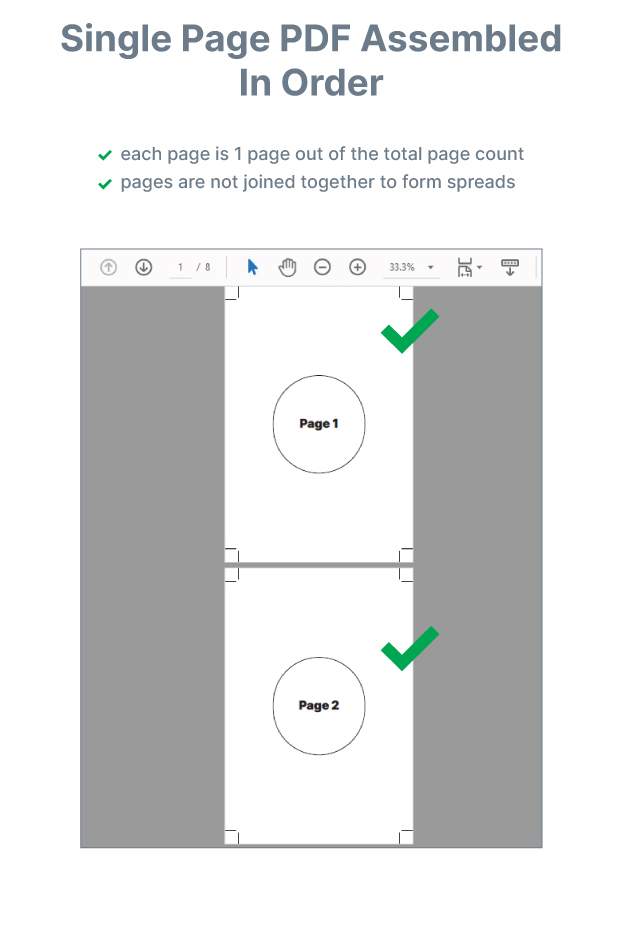

You can choose to supply the cover as part of the interior, or supply two files (cover and interior separate). The diagram below shows what a single-page PDF looks like, in comparison to a spread.

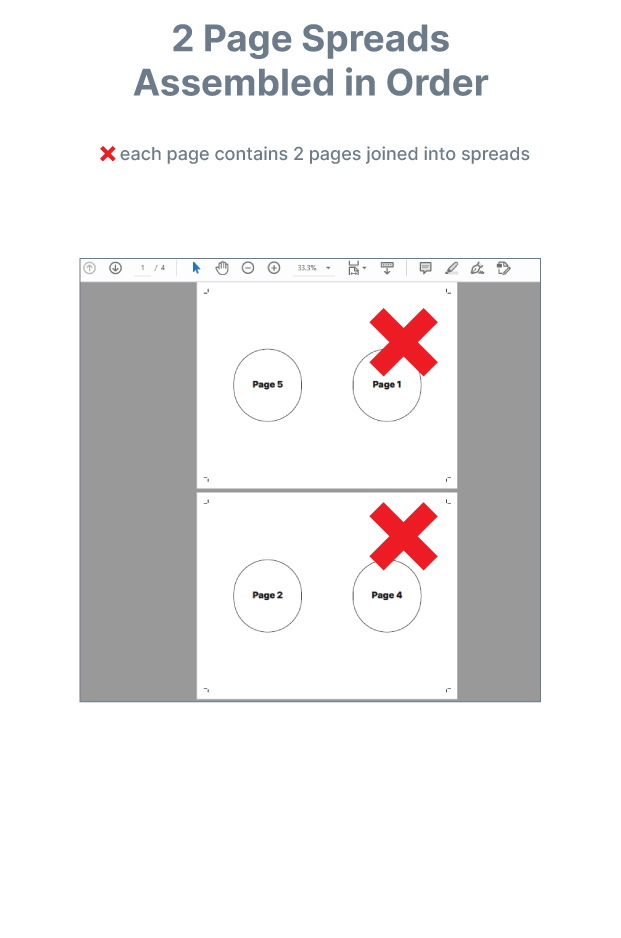

If you supply pages as spreads, then your PDF file will display two pages together on one PDF page, creating spreads. We ask that you do not supply files as spreads, always supply files as single page PDF’s assembled in order.

Booklet Production Process

The diagram below shows the production process of a saddle-stitched booklet, and how 4 pages are printed per signature.